Manufacturing expertise

This ASSY® screw with our RW drive is part of the fourth generation of wood screws developed and manufactured by Würth. It is the product of a wealth of expert and customer knowledge gleaned from three decades. It is easy and safe to use, as has been confirmed by extensive tests and expert opinions.

Manufacturing expertise

This ASSY® screw with our RW drive is part of the fourth generation of wood screws developed and manufactured by Würth. It is the product of a wealth of expert and customer knowledge gleaned from three decades. It is easy and safe to use, as has been confirmed by extensive tests and expert opinions.

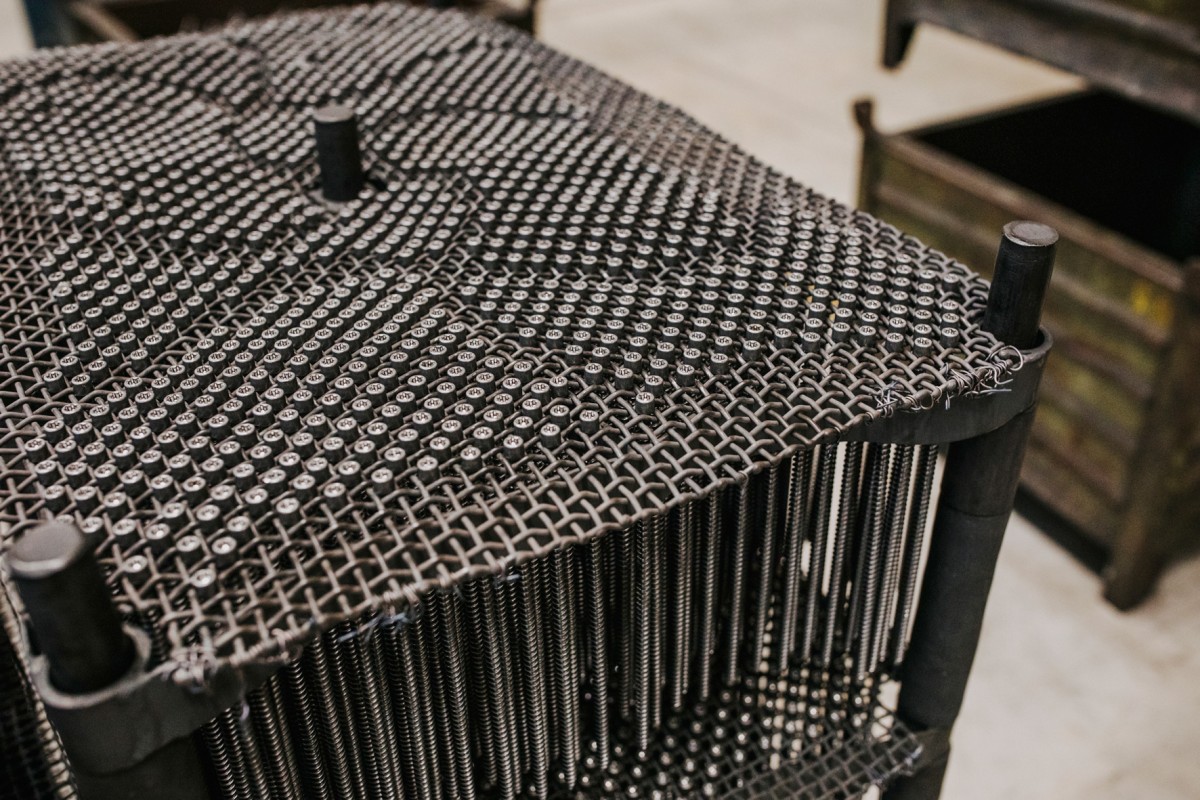

Regional production

The screw is manufactured in the region at the subsidiary SWG, just nine kilometers from the Würth Group’s headquarters in Künzelsau. Short transportation routes translate into a good carbon footprint.

Regional production

The screw is manufactured in the region at the subsidiary SWG, just nine kilometers from the Würth Group’s headquarters in Künzelsau. Short transportation routes translate into a good carbon footprint.

Extended family

This ASSY® screw has 1,599 siblings, and every one of them is unique. They differ in terms of their diameter, material, surface, length, and geometry.

Extended family

This ASSY® screw has 1,599 siblings, and every one of them is unique. They differ in terms of their diameter, material, surface, length, and geometry.

A source of impetus

Designed for use in structural timber engineering, the ASSY® screw provides impetus for sustainable construction. As a renewable, energy-neutral raw material, wood captures CO2, making it more environmentally friendly than other building materials like concrete.

A source of impetus

Designed for use in structural timber engineering, the ASSY® screw provides impetus for sustainable construction. As a renewable, energy-neutral raw material, wood captures CO2, making it more environmentally friendly than other building materials like concrete.

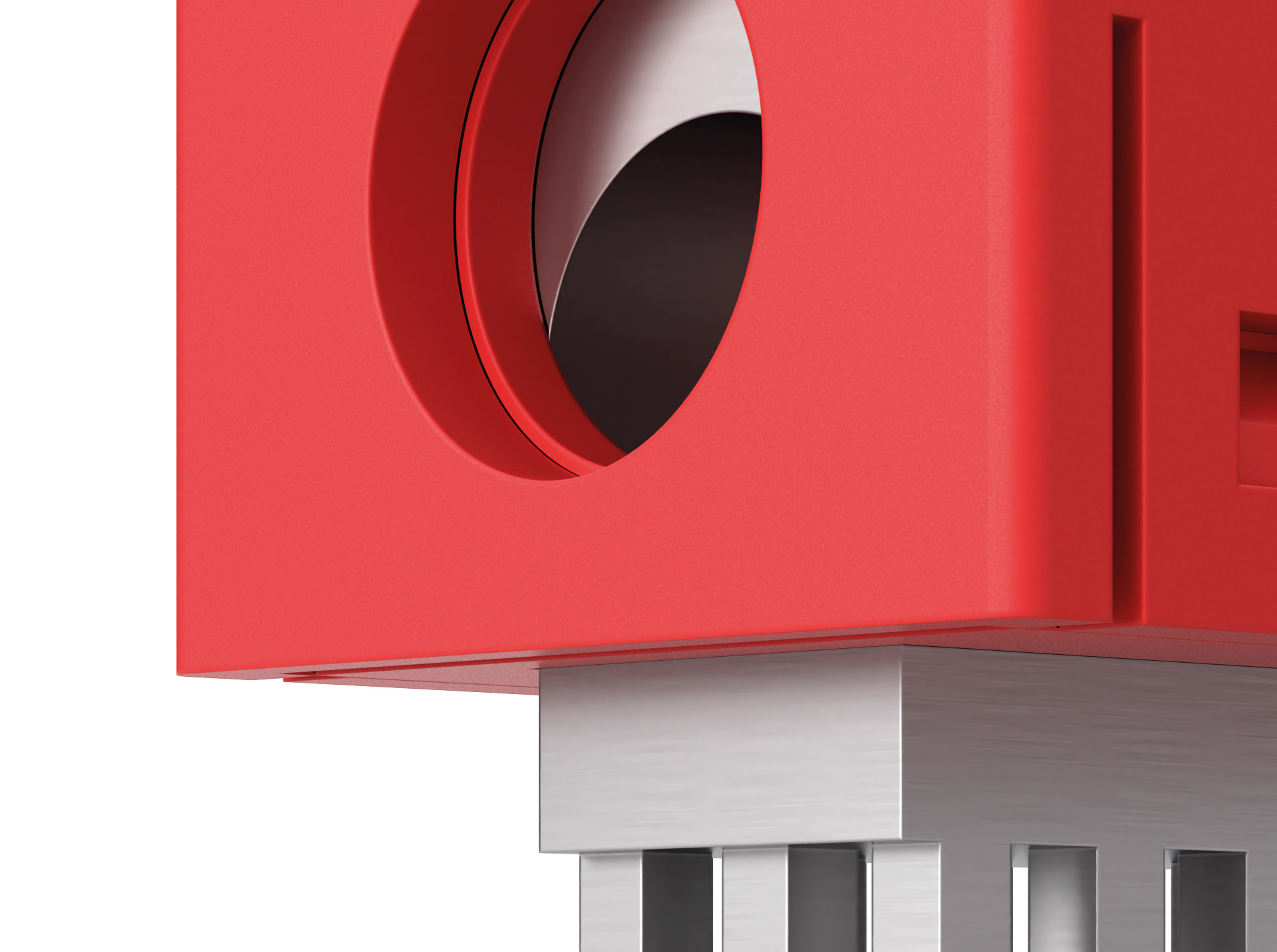

Digital service

How many ASSY® timber screws do I need? Where should I install them and which screw connection should I use? Design software provides a quick overview. Load tables show the weight each screw can support, depending on its head shape, diameter, and thread length.

Digital service

How many ASSY® timber screws do I need? Where should I install them and which screw connection should I use? Design software provides a quick overview. Load tables show the weight each screw can support, depending on its head shape, diameter, and thread length.

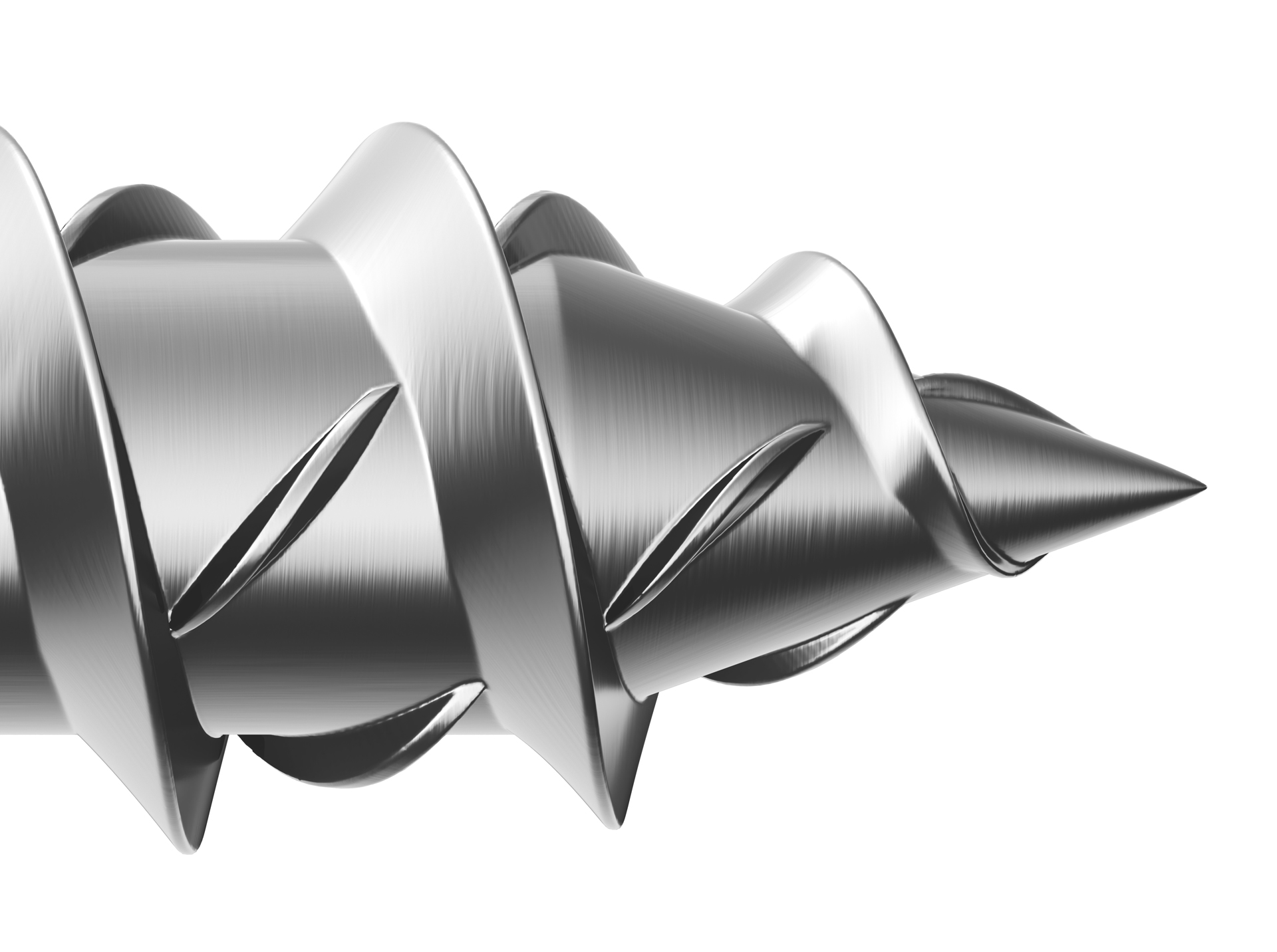

The perfect combination

The RW drive transmits forces even more effectively. Smart details such as the end mill, new tip, and thread geometry make it more straightforward, easier and faster to drive the screw in. Two bits are usually enough for a carpenter. The technology and the combination of details are what make the difference.

The perfect combination

The RW drive transmits forces even more effectively. Smart details such as the end mill, new tip, and thread geometry make it more straightforward, easier and faster to drive the screw in. Two bits are usually enough for a carpenter. The technology and the combination of details are what make the difference.