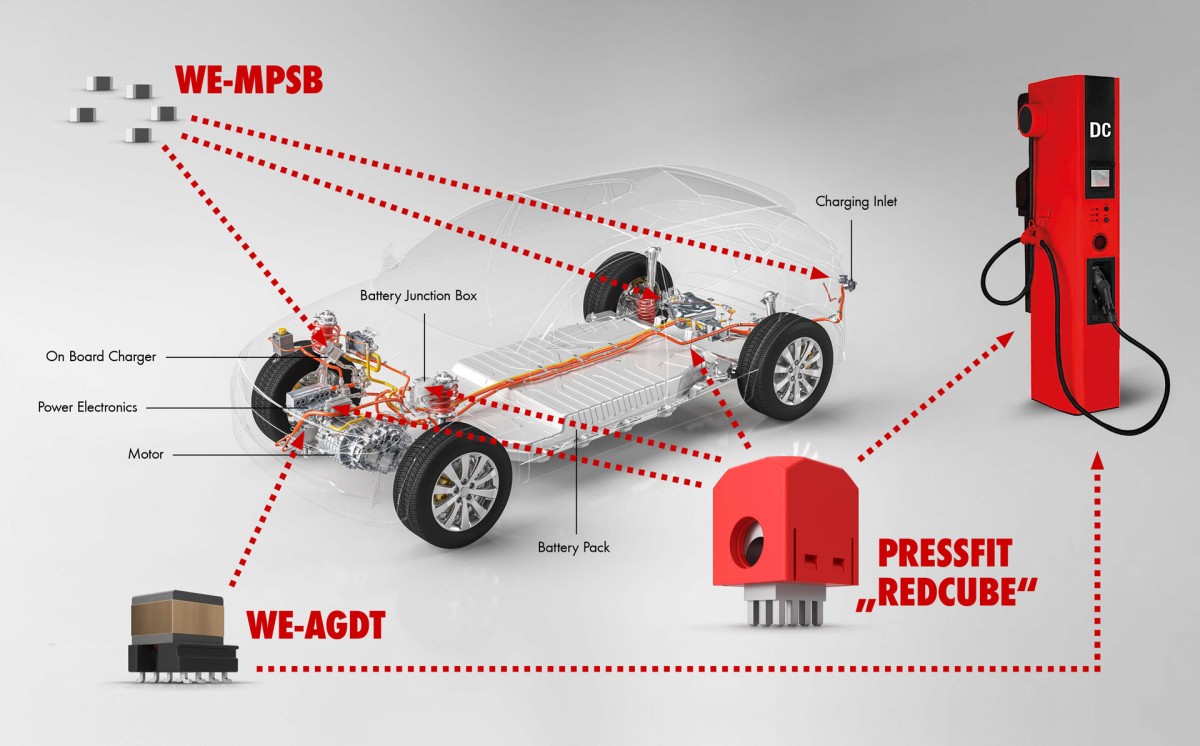

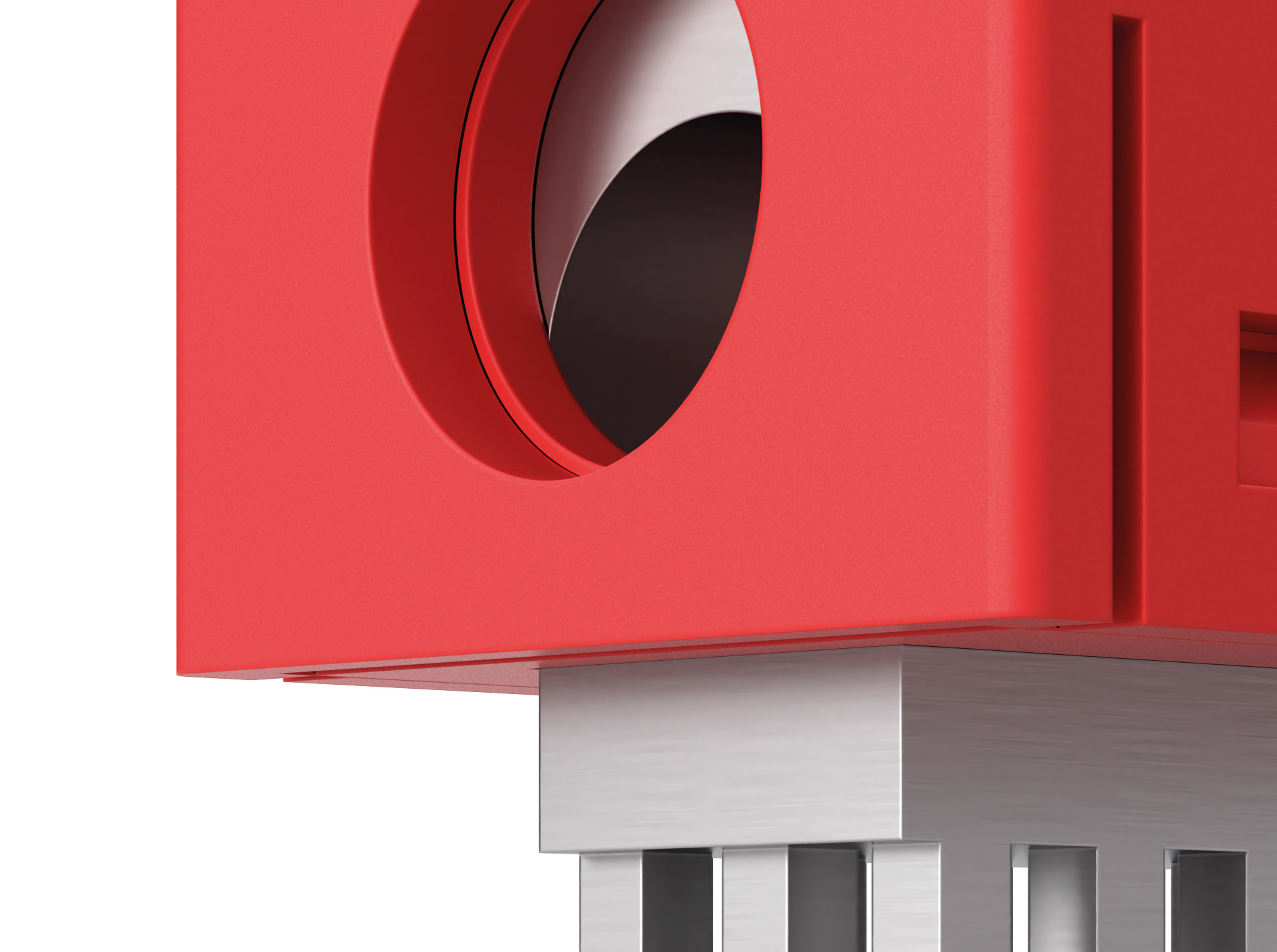

Charging time of less than 30 minutes

Less than half an hour and an electric vehicle with an empty battery is ready to go again. The REDCUBE® components from Würth Elektronik are built to withstand 350 kilowatts of charging capacity. Combined with press-fit technology to ensure the safe transmission of strong currents, they ensure that the battery is fully charged again quickly.

Charging time of less than 30 minutes

Less than half an hour and an electric vehicle with an empty battery is ready to go again. The REDCUBE® components from Würth Elektronik are built to withstand 350 kilowatts of charging capacity. Combined with press-fit technology to ensure the safe transmission of strong currents, they ensure that the battery is fully charged again quickly.

Up to 10 percent more range

The WE-AGDT power transformer is no bigger than a fingertip. Würth Elektronik developed it for the new silicon carbide (SiC) semiconductor technology in electric vehicles. When combined with a SiC semiconductor, the component increases powertrain efficiency, reduces power consumption, and increases the range of electric vehicles by up to 10 percent.

Up to 10 percent more range

The WE-AGDT power transformer is no bigger than a fingertip. Würth Elektronik developed it for the new silicon carbide (SiC) semiconductor technology in electric vehicles. When combined with a SiC semiconductor, the component increases powertrain efficiency, reduces power consumption, and increases the range of electric vehicles by up to 10 percent.

A 30 to 50 percent longer service life

The WE-MPSB electronics component is almost unshakable: It reduces unwanted electromagnetic radiation and has the power to withstand vibrations and extreme temperatures. This helps extend the life of electric vehicles by 30 to 50 percent.

A 30 to 50 percent longer service life

The WE-MPSB electronics component is almost unshakable: It reduces unwanted electromagnetic radiation and has the power to withstand vibrations and extreme temperatures. This helps extend the life of electric vehicles by 30 to 50 percent.

Tiny

So that you can see the WE-MPSB component, which is only a few millimeters in size, the image shown here has been magnified five times. Small but powerful!

Tiny

So that you can see the WE-MPSB component, which is only a few millimeters in size, the image shown here has been magnified five times. Small but powerful!